| Watches by Machinery An article found in the spring issue of Harpers 1869. It is about the new factory at Elgin Illinois. "WHAT o'clock is it?" asked Emanuel Swedenborg, upon his deathbed. Being told, he answered, "It is well; I thank you; may God bless you;" and the pure spirit of the venerable teacher gently passed away. "What o'clock is it?" ask little children, as they blow off the feathered seed-vessels of the dandelion, and tell the hour by the number that remain upon the stalk.

Civilized man every where, from the cradle to the grave, repeats this question oftener than any other. Were all things at rest it could never be answered. Motion alone enables us to measure time. Motion is best exemplified in the heavenly bodies, particularly the sun. Yet man, "the tool-making animal," never asks, "What o'sun?" but simply "What o'clock?" He has brought artificial timekeepers to such perfection that they are the most wonderful of his mechanical achievements, the things most alive and human in the entire range of his handiwork. Primitive man had little need of clocks or watches. The opening and closing of flowers; the voices of birds, beasts, and insects; the position of sun, moon, and stars, told the passage of time with accuracy enough for his simple life. Mariners, hunters, shepherds, and all other men much alone with nature, still keep familiar with her habits and her moods. The Indian says, "Four moons have passed," or "It was ten sleeps ago;" and the farmer, "It was between day and sunrise," or "It was half an hour by sun." Job's expression, "As a servant earnestly desireth the shadow," points to the earliest artificial timekeeper. The sundial (dialis, daily) originated, nobody knows when, with some of the Eastern nations. Isaiah wrote, eight hundred years before Christ, "I will bring back the shadow of the degrees which is gone down in the sundial of Ahaz ten degrees backward." A dial, usually standing upon a stone post on a sunny knoll, is still preserved as a relic of the past in almost every English country churchyard. Around it on Sunday mornings, an hour or two before service, were wont to gather the rustics, discussing crops, the weather, and politics, while matrons gossiped soberly, and children tumbled in leapfrog over mossy tombstones, or played ball against the tower, till the parson's tinkling bell summoned all to worship. In clear weather the dial showed the hour by day, as the stars did by night; but when clouds came something more was needed. Hence the East originated the "Clepsydra" (the " Water Stealer"), a transparent, graduated vase filled with liquid, which slowly trickled or stole away through a little aperture in the bottom. The receding height marked the passage of the hours. The clepsydra was used in ancient China, and in Egypt under the Ptolemies. Caster found it among the native Britons. Pompeii introduced it into Roman courts " to prevent babbling." One of Martial's epigrams counseled a dull declaimer, who was constantly quaffing from a glass of water during his endless harangue, to relieve both himself and his audience by drinking from the clepsydra instead.

Clepsydra. In the Colony of Massachusetts Bay two centuries ago an hour-glass stood before the Puritan preacher, and was turned by a tithing-man when he began his sermon. lf he stopped long before the sand ran out, his bearers were dissatisfied; if he continued long after, they grew impatient.

Hour glass. The hour-glass is only a modification of the clepsydra. It substitutes fine sand for water, as something which will neither freeze nor evaporate, and which, when the glass is full, will run little faster than when it is nearly. empty. It was known before the Christian era, and has been used by nearly all nations. It was so common among our ancestors a hundred years ago that the illustration which we copy from the New England Primer of 1777 was drawn from one of the most familiar objects in their daily life. In dry, equable Eastern climates the clepsydra long maintained its supremacy, and it is used in India even to this day. It was exceedingly inaccurate, but improvements were constantly added. Sometimes water flowed in tears from the eyes of automata, and sometimes a floating statue rising and falling with the liquid pointed to the passing hours engraved upon an upright scale. Next, a little wheel was introduced, on which the water fell drop by drop, turning it, and thus communicating motion to hands upon a dial. In time machinery was inserted to tell not only the hours of the day, but the age of the moon, and the motions of other heavenly bodies; and finally the clepsydra grew into an ingenious and complicated waterclock, A thousand years ago a Persian caliph, the Haroun-al-Raschid of the Arabian Nights, sent one to the Emperor Charlemagne which had a striking apparatus. When the twelve hours were completed twelve doors opened in its face; and from each rode an automaton horseman, who waited till the striking was over, and then rode back again, closing the door after him.

"Clock" originally signified "bell, " and the French cloche still retains that meaning. The invention is claimed for many different peoples and eras, from the Chinese two thousand years before Christ down to the Germans of eight centuries ago. The first general use of clocks was in monasteries, during the eleventh century. Before their appearance the sacristan sat up to watch the stars that he might waken the monks at the hours of prayer. The common people attributed their origin to the devil; and had any body outside of the religious orders incurred the odium of first introducing them, he would doubtless have been put to death as a sorcerer.

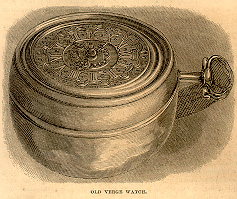

Ships chronometer. For several hundred years they were exceedingly rude and irregular. But not long after the Pilgrims landed at Plymouth, Galileo, while noticing the vibrations of a hanging lamp, discovered the great principle of the pendulum that when a suspended body is swinging, any increase or decrease of its speed will not change the number of vibrations it makes in a given time, but only the length of the arc it describes. The pendulum was soon applied to the clock, and added greatly to its accuracy. Public clocks nevertheless have always been tempting marks for the shafts of satire. The proverb, "As untrustworthy as a town clock," still continues in vogue; and there is a witty saying in Peterborough, England, that if the clock of the cathedral and that of the parish church ever strike simultaneously there will be a death in the minster yard. Until after the Revolution the American colonies had few clocks of any kind. Sun-dials and hour-glasses sufficed for those leisurely days. Why is it that the more we multiply inventions for saving time and labor, the more we are pressed for minutes, and the harder we have to work? Thirty years ago " The varnished clock that clicked behind the door" was the great domestic time-keeper. Who has forgotten its monotonous "click-clack, "or its quaint, upright case, taller than a man ? What true Yankee boy ever failed, sooner or later, to take it to pieces, and see how it was made? Or the kitchen bellows, cut open to learn what was inside, was very disappointing; but the old family clock, surreptitiously dissected, proved its own exceeding great reward. Until within the last two or three generations all our time-keepers were made in Europe. Now, Connecticut clocks tell the hour at Jerusalem, at Calcutta, at Pekin, and at Irkoutsk. At our factories a fair little clock., neatly eased, can be afforded for eighty cents gold. American inventiveness has done it! Town clocks and chronometers are reguIated from the nearest observatories. But the electrical clock will do away with that. One at some central point will serve for a city as large as New York. Wires connecting with dials on all the church towers, and, indeed, in all the dwellings, may regulate the hands of every clock in the metropolis to perfect uniformity. When the telegraph nerves run into every house we shall all get the time of day from a common source, as we do gas and water. The ship chronometer-for determining longitude at sea was invented in 1675. One costs about four hundred dollars. The most are of English manufacture, though there are half a dozen makers in the United States. A few years ago the Greenwich Observatory paid a premium of three hundred pounds for a chronometer which had varied only about one second in twelve months. It makes no difference whether one is fast or slow; all the shipmaster requires is that it shall run with regularity. No other invention since the mariner's compass has so diminished the perils and uncertainties of navigation. Watch is from a Saxon word signifying "to wake." At first the watch was as large as a saucer; it had weights, and was called " the pocket clock." The earliest known use of the modern name occurs in a record of 1542, which mentions that Edward VI. had " onne larurm or watch of iron, the case being likewise of iron gilt, with two plumettes of lead." The first great improvement, the substitution of the spring for weights, was made about 1550. The earliest springs were not coiled, but only straight pieces of steel. Early watches had only one hand and required winding twice a day. The dials were of silver or brass; the case; had no crystals, but opened at back and front, and were four or five inches in diameter. A plain watch cost the equivalent of $1.500 in our currency, and after one was ordered it took a year to make it. There is a watch in a Swiss museum only three-sixteenths of an inch in diameter, inserted in the top of a pencil-case. Its little dial indicates not only hours, minutes, and seconds, but also days of the month. It is a relic of the old times, when watches were inserted in saddles, snuffboxes, shirt-studs, breast-pins, bracelets, and finger-rings. Many were fantastic oval, octangular, cruciform, or in the shape of pears, melons, tulips, or coffins.

Mary Queen of Scots skull watch. Mary Queen of Scots had a large one in the form of a skull, which is still preserved by a gentleman near Edinburgh. The case is opened by dropping the under jaw, which turns upon a hinge, while the works occupy the place of the brain. Old verge watch. Old watches are common in English museums. There are comparatively few in the United States; and I know of none of American manufacture much over fifty years old. F. W. Chamberlain, of No. 233 Hanover Street, Boston, has upward of two hundred-much the largest and rarest collection on our continent. One of the most curious is an old English verge, two inches thick. If it were only half as large it would be a perfect specimen of the ancient bull's-eye.

Another of Chamberlain's treasures-also an English verge-is over two centuries old. One would like to see a photograph of the man it was made for, Knee breeches, horsehair wig,and all. It keeps excellent time, not varying two minutes a week, though its little heart has throbbed on while six generations of owners have wound it, and carried it, and left it at the jeweler's for cleaning have been born by it, and lived by it, and died by it. A third is a French striking watch two hundred years old, with elaborate ornamentation, and allegorical male and female figures on the dial. When the works within strike the hours these figures pound with hammers upon little counterfeit gold bells, as if they produced the sound. The ticking of a watch-the beating of its heart-is the playing of the two arms of the pallet in between the teeth of the escape wheel, at the point where the rotary motion of the wheels or "train" changes -to the vibratory motion of the balance. In nine cases out of ten a skilled watch-maker can tell whether there is any thing wrong with a watch, and if so, what, by putting it to his ear" as a skilled physician learns the condition of the human timekeeper by feeling its pulse or~ bearing its heart.

The mainspring is the locomotive, the wheels are the train, and the balance and hair-spring the brakes. When the mainspring is first wound up its force is much greater than when it is nearly run down. The old barrel and fusee watch equalized this by making the fusee spiral. When the mainspring was fully coiled, and pulled hardest, it acted upon the small end of the fusee, where the most power was needed. As the spring grew weaker the chain descended to where the fusee was larger, and required less force to turn it. The English yet retain the spiral fusee, on their national theory that whatever is old ought to continue. The American watch dispenses with the fusee altogether, perhaps on our national theory that whatever is old ought to be abolished. Its mainspring instead communicates motion directly to the train, and its nice adjustment of hair-spring and balance-wheel insures equal time through the twenty-four hours. When a watch is first wound up the balance may make one revolution and a half at each impulse from the escape-wheel, and when it is nearly run down, only half a revolution; but the former will consume no more time than the latter, and so the watch goes uniformly through the twenty-four hours. How shall it be made to go uniformly through summer and winter? A steel rod maybe fitted into a hollow steel cylinder so perfectly that it will not drop out of its own weight, and yet it can be turned or pulled out by the thumb and finger, and it moves with the softness of velvet rolling on velvet. Hold the same rod in the shut hand for five minutes and the warmth of the flesh will expand it so that one can not drive it in with a sledge-hammer. Then put it in a refrigerator and it will contract till it rattles in the cylinder. If the metal is brass, temperature affects it still more. Winter will so contract the balance-wheel of a watch that it may gain two minutes in a day; or it may be thrown out of time by a few hours' sleigh-riding, or by hanging all night against a cold wall. Uneven temperature is the deadly foe of uniform time-keeping. In 1767 John Harrison was awarded a premium of L20,000, under an offer of the British Parliament- which had been standing fifty three years-for any invention which should so far overcome this difficulty as to enable shipmasters at sea to determine longitude within thirty miles of accuracy. He gained it by applying to ship chronometers the principle of the compensation-balance, now used in all fine watches. It is simply a balance-wheel with outer rim or tire of brass, and inner rim and cross arm of steel. The cold, which would Contract steel alone and make the circumference of the wheel less, equalizes that by contracting the brass still more, the brass being so confined that its contraction enlarges the wheel. Under the influence of heat the steel's expansion would enlarge the wheel, but then the greater expansion of the brass contracts it. When these two influences are so nicely adjusted that the one exactly counterbalances the other, the watch will keep equal time whether in Alaska or Havana. Until very lately American jewelers imported wheels, balances, and other material ready made from Switzerland, fitted the various parts together by band, put their stamp upon them, and called that watchmaking. Its art and mystery was acquired in an apprenticeship of from three to five years. In Switzerland, division of labor had been introduced long before. Each workman performed some one process of shaping, cutting, or finishing parts of the watch in his own little shop at home, and returned the parts to the manufacturer, as bootmaking is done in New England. And for many processes, little labor-saving machines, run by foot lathes, had come to be used. In 1852, A. L. Denison, a Boston watchmaker, conceived the plan of producing watches by collecting all these machines under one roof, and running them by one power. His wild dream was that a time might come when a manufactory could turn out ten watches a day. Most of his friends voted him crazy, but he had the one quality which makes all lunacy contagious-profound earnestness. He soon made Edward Howard, David P. Davis, and Samuel Curtis as mad as himself, and the four lunatics built a factory in Roxbury. But the Swiss authorities would not permit the export of machines, models, or drawings; so, Yankee-like, the four pioneers invented and constructed machines for themselves. Finally, they turned out a watch, the first ever made by machinery in the world. It is yet in Mr. Howard's possession, and keeps excellent time. The machines were very imperfect, and much of the work was still done by hand. But from that beginning have sprung all our watch factories, I now situated respectively in Elgin, Illinois, Newark and Marion, New Jersey, and Waltham, Roxbury, and Springfield, Massachusetts. As we step aboard the Galena train at Chicago we observe the placard, "Pacific Express; does not Stop at Way Stations." We ponder behind the locomotive for forty miles; then the brakeman ends our reverie by shouting "Elgin.

Leaving the train, we gaze down upon a far spreading little city, with courthouse, academy, and churches upon commanding knolls, brick blocks and broad streets, cottages pleasantly shaded with oak, maple, and poplar, a woolen mill, a flouring mill, a butt-and-screw manufactory, and a milk-condensing establishment that ships its product to New York-all beside the bright river which cuts the town in twain, and is spanned by a gossamer iron bridge; and over the housetops, a mile away, the tall chimney of the National Watch Factory. In the spring of 1864 half a dozen active business men of Chicago, heard a fascinating description of the leading Massachusetts watch factory. Yo their willing ears it was a story with a moral, and this was the moral: "If Boston can make watches by machinery and Chicago can largely supply the Northwest, Chicago can make watches by machinery and largely supply New England." It was the genuine, audacious, self-reliant Western spirit. Practical workmen assured them that with the investment of a hundred thousand dollars in buildings and machinery they could begin to turn out watches. They added fifty per cent to this estimate for a margin, and with that blessed unconsciousness of the difficulties before them, without which no great enterprise would ever be undertaken, they organized the National Watch Company, and in November the work began.

After two years and a half spent in constructing the hundreds of intricate machines and erecting the buildings, in May, 1867, the first watch was completed. Not, however, until long after the first hundred and fifty thousand dollars was exhausted-that barely sufficed for a beginning. Before the enterprise was self-sustaining more than five hundred thousand dollars bad been expended, and its owners and friends would doubtless have doubled that sum rather than permit it to fail.

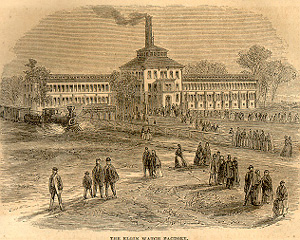

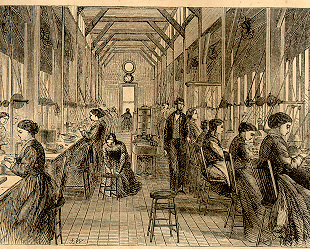

A factory 20 years ago. The watch factory of twenty years ago-let pencil and graver fix its humble features ere the place which once knew it shall know it no more forever. The tiny building, with its sign, "John Smith, Watchmaker," the single room, eight by ten, with its counter, showcase, and window bung with watches, and its one workman, who repaired fifty watches a year, and "made" two or three at odd times. Here and there one of these establishments yet exists, but it is as really a relic of antiquity as a hand-loom or a wooden plow. The National Watch Factory at Elgin is a specimen of the great museums of machinery and beehives of workmen which have pushed it from its stool. The front, shown * in our illustration, is two hundred and forty feet long. Several other wings are hidden in the rear, The cars of the Fox River Railway deliver material at the very door. My first view of the factory yard was toward the close of the noon hour ' when the employees were pouring back from dinner. It was a fair picture. On one side the gleaming river, with white and spotted cattle grazing upon its bank; on the other a grove of young oaks, their leaves falling from autumnal frosts; in the foreground scores of ruddy-cheeked girls sauntering back toward their work, while quiet artisans smoked their cigars and meerschaums upon the factory steps and a little platform where a band of operatives discourses music on Saturday afternoons in summer. A dozen young men were jumping, with dumbbells in their hands, each trial calling out shouts of applause or merriment; and a score of boys playing baseball as if their salvation depended upon it. Suddenly the great bell set behind the factory struck for one o'clock, and the swarm of life poured into the building. The employees are equally divided between the sexes. I never saw so many boys and girls in an Eastern manufactory. The working day is ten hours. Whenever the welcome bell proclaims the hour of noon , or six in the afternoon, these young people give a whoop like released schoolchildren, and can hardly wait to put away tools and make benches tidy before they join the merry throng streaming homeward. The average earnings of the girls are something over six dollars per week-in a few cases as high as twelve; those of the boys and men three dollars per day. Board for girls costs about three dollars per week; for men, from five dollars upward. "That little girl," said the superintendent of the Steel Room to me, " can do any thing in this large department as well as any man in it;" and a number of similar cases were pointed out to me.

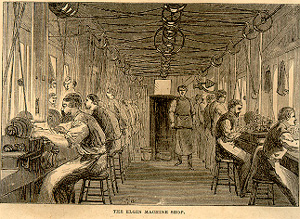

The Machine Shop The Machine Shop-a hundred feet long, with thirty brawny, bare-armed workmen-is the letter A in the alphabet of the watch factory. |

Here all the tools and machines are

manufactured and repaired. Their name is legion; their sizes are

innumerable. They include machines which will take a shaving off a hair,

and those which will slice up steel like apples; registers that will

measure the twenty-five hundredth of an inch, and registers that will

measure a foot; drills for making holes invisible to the naked eve, and

drills almost as large as crowbars; and so on ad infinitum. I will not

attempt to describe the "cams," "taps,"

"clamps","quills","reamers","eccentrics","chucks," and wigwags." The one

thing a which strikes a novice is the wonderful accuracy and minuteness,

the beautiful smoothness and polish of every thing. The finest jobs of

ordinary machine-shops would be thrown aside here as utterly worthless.

Punching the wheels. The works of a watch, not counting the plates which form the shell or frame, are of brass and steel in nearly equal proportions. And,by-the-way, why is "brassy" a term of denunciation, and "as true as steel" the language of compliment, when brass may be made nearly as hard as steel, and will take almost as fine a temper? Steel is used in a watch wherever there is great strain upon some very slender part. But where there is much friction between two wheels one must be of brass and the other of steel. By some mysterious law of metals these will outlast two wheels of the hardest and most highly polished steel twice over.

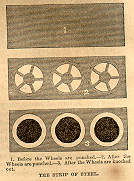

The strip of steel. Great sheets of brass and steel are first received in the Punching Room, where an enormous pair of shears cuts them into ribbons. These are lengthened and thinned between a pair of steel rollers, which, if required, will leave them only one-four-thousandth of an inch thick. One of these ribbons is then passed slowly between the punch and die of a huge press, driven by a heavy wheel which a workman controls with his foot. The punch rises and falls with the motion of the wheel, coming down each time with a weight of twenty tons, and with a "click," cutting Out a perfect spoked wheel. The press is an enormous monster which bites out mouthfuls of steel but refuses to digest them. Like most monsters, however, it will do no damage if it is only fed. It leaves the wheels fast in the strip to be knocked out by hand. With it a man can cut out ten thousand wheels in a single day. Next we visit the Plate Room. The upper and lower brass plates are respectively the roof and floor of the watch. The upper one must have thirty-one holes bored in it, for pillars, pivots, and screws. A little girl cuts them with a needle-like drill, which revolves like lightning, and goes through the thick plate in a twinkling. Another girl, with a chisel whirling with equal rapidity, cuts away the ragged burs or edges left on the side where the drill comes out. This "countersinking," which leaves a cuplike depression, is performed wherever a hole is drilled through brass, steel, or jewel.

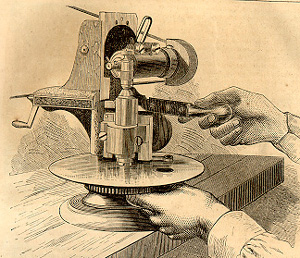

The four pillars-the posts which are to bind roof and floor together are made and inserted in the lower plate by a miraculous little contrivance, which a coffee saucer would cover. The punching machine is a behemoth, but this is a fairy. it seizes one end of a brass wire, and in eleven seconds measures off a pillar, turns it down to the required size, makes a screw-thread in each end, cuts it off, and screws one end into the lower plate so firmly that we can not unscrew it with a pair of pincers. But it keeps the workman's feet busy, and his hands flying as if he played a lively tune upon the piano. He will easily make and insert two thousand pillars in a day. By hand he could hardly make two dozen. When the brass pieces are finished, all belonging to one watch are stamped with the same number and put into one of ten little boxes hollowed out in a board like birds'-nests. The nests have yet many journeys to make before the eggs are hatched; but the shell or frame is now ready for the works. The tipper plate is next engraved. Three men and four girls are kept busy tracing the elaborate scroll-work, and the inscription, "B. W. Raymond, Elgin, Illinois, No. 41,280," or "J. T. Ryerson, No. 41,290," as the case may be. The different grades made here are "Lady Elgin," "B. W. Raymond," "Mat Laflin," "G. M. Wheeler, " " H. Z. Culver," " H. H. Taylor," and "J. T. Ryerson;" but the numbering runs consecutively through all.

The screws in a watch number forty-four, or more than one-quarter Of all its pieces. The Screw and Steel Department is one of the largest in the factory. Its magical little automata, run by nimble-fingered girls, convert shining steel wire into infinitesimal screws, pare down their heads, and cut slots in them for microscopic screwdrivers. They are polished to perfect smoothness, and then, like every other part of the watch, brought to "spring temper"-the temper of the sword-blade-by beating, which leaves them of a rich, deep blue. The illustration shows the screws of their actual size, and also one magnified 100 times each way, or 10,000 times the actual size. Here are machines which will cut screws with five hundred threads to the inch ; the finest used in the watch have two hundred and fifty. Even these threads are invisible to the naked eye, and it takes one hundred and forty-four thousand of the screws to weigh a pound. A pound of them is worth six pounds of pure gold. Lay one upon a piece of white paper, and it looks like the tiniest steel-filing. Only by placing it under a strong magnifier can we detect its threads and see that it is shining as a mirror, and as true and perfect as the driving wheel of a locomotive. Screws for the best compensation-balance are of gold. A ten-dollar piece will furnish material for six hundred and fifty of them.

The compensation balance comes from the Punching Room a solid piece of steel as large and heavy as a new penny, and inclosed in a rim of brass. It is ground down, worked out, and polished till it becomes a slender wheel the outer rim brass, the inner rim and crossbar steel-lighter and thinner than a finger-ring. Through the double rim twenty-two holes are drilled for the screws. A chuck whirls the wheel around-as one would spin a penny upon the table-four thousand eight hundred times a minute, while a lad makes each hole by applying three tiny drills one after the other. He will bore one hundred wheels per day, or apply a drill oftener than once in six seconds from morning till night-to say nothing of the time consumed in fastening on and taking off the wheels and sharpening his drills. Screws of gold or brass are then put in, and the balance is completed. On this little part alone nearly eighty operations have been performed.

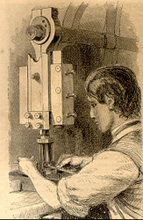

The train room. Next we step into the Train Room, the largest and pleasantest in the factory. Seventy-five persons with busy fingers sit at six rows of benches extending its entire length, each before some little machine, shaping, smoothing, pointing, grinding wheels, pinions, or pivots. Cutting teeth in the wheels is done by piling up twenty or more, with an upright shaft passing through the centre of each, and turning a screw to hold them together. The girl in charge then lifts one handle of a little machine, and instantly a steel cutter like a shingle-nail, but with a sharp point at one end, is brought against them, whirling so fast that it looks like a perfect wheel. Whizzing down the outer edge of the pile, it cuts a groove or furrow in each wheel, When it reaches the bottom she moves the other handle; the cutter flies up to the top, and runs whizzing down again. A single wheel has from sixty to eighty teeth, but the girl will finish twelve hundred wheels a day. The long, hooked teeth of the scape-wheel, and the horn shaped tooth of the ratchet, are cut with equal facility.

Cutting the teeth. In the Escapement and Jeweling departments we first encounter precious stones, in which pivots of brass or steel will run for generations without any perceptible wearing. In the order of hardness they stand, diamond, sapphire, white or milky ruby, red ruby, garnet, aqua marine. In jewk ' they are valued only for their color, in watch-making only for their hardness. Montana begins to supply garnets, but most precious stones come from India, Persia, or Brazil. They are always bought by the carat-theone-hundred-and-twentieth part of an ounce Troy-no matter how large the quantity. They are used not only for jeweling, but also for tools to cut other precious stones or hard metals with. Sapphire is the favorite, because it can be sharpened upon diamond, while a chisel of diamond -the hardest of all known substances -must either be broken to give it a fresh edge, or sharpened slowly and laboriously against another diamond. The Dutch are the most famous lapidists in the world. They sent workmen from Amsterdam So London to cut the great Koh-i-noor. They will divide a diamond weighing but one carat into two hundred and fifty little slabs, which look like fairy finger-nails. Inserted in brass handles they become ridiculous little chisels, which might turn out wheels and axles for Queen Mab's chariot. Diamond dust also, as white as snow, and finer than flour, has a hundred uses in the factory. An ounce costs five hundred dollars. Metal edges for cutting and surfaces for polishing are "charged" with it; that is, a little of the powder is firmly imbedded in them, and gives them a sharpness which nothing can resist. Some rare watches are jeweled with diamonds and sapphires, and many with rubies; but for all practical purposes garnets and aqua marines answer as well. The "Lady, Elgin," an exquisite little time-keeper, has fifteen jewels, all of ruby. Four of the fifteen in the " B. W. Raymond" are of ruby, the rest of aqua marine and garnet. The precious stones are cut into planks, and then into joists, by circular saws, and afterward broken into cubes. Then each is turned out in a lathe, exactly as a bed-post is turned in a furniture factory. By this time it weighs less than one- eighty-thousandth of a pound Troy. It is afterwad burnished into its setting-a little circular rim of brass. The hole is made through it with a diamond drill, barely visible to the naked eye, and polished with another wire which passes through it and whirls one way while the jewel whirls the other. The two make twenty eight thousand revolutions a minute. Finally jewel and setting are inserted in a little depression of the watch-plate, which they exactly fill, and held in place by tiny screws of steel, whose deep blue contrasts pleasantly with the bright gilding of the plate. Every part of a watch must be absolutely accurate, but no part must fit perfectly. To run freely each pivot must have a little play, like a horse in harness; otherwise the least bit of dirt or expansion of metal would stop the delicate machinery. So every jewel-hole is left a little larger than the pivot which is to revolve in it for the "side-shake," and every shaft or axle a little short for the "end shake." The tiny gauges which measure all the parts make allowance for this-a bit of calculation which they perform with an ease and accuracy unknown to poor human brains. There is another danger to guard against. If the least grain of diamond dust is left in a jewel-hole it will inbed itself firmly in the steel pivot, and then act as a chisel, cutting away the jewel every time the pivot revolves. The new dust of ruby or garnet which this produces will act in the same way" diamond cut diamond"-until the jewel is utterly ruined; so the utmost care is necessary to see that no particle of diamond dust remains in the watch. After the jeweling is done the birds'-nest boxes go to the Finishing Room. In following, let us stop to glance at the Dial Department.

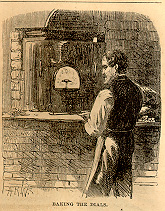

Baking the dial. The dial, a plain circular plate of Lake Superior copper,'no thicker than a silver three cent piece, is first covered with a paste of fine white enamel, carefully spread on with a knife, to the thickness of three-one-hundredths of an inch. After it dries a little, a workman with a long pair of tongs places the dial flat upon a red hot iron plate In the mouth of a glowing furnace,watching it closely and frequently turning it. The copper would melt but for the protecting enamel, and, at the end of a minute, when he takes it out it is as soft and plastic as molasses candy. The baking has "set" the enamel, but has left it rough, as if the dial face were marked with small-pox. After cooling it is ground smooth upon sandstone and emery, and then baked again. Now it is ready for the painters. A girl draws six lines across its surface with a leadpencil guided by a ruler, making each point for the hours. Another with a pencil of black enamel traces coarsely the Roman letters from I to X11. A third finishes them at the ends to make them symmetrical. A fourth puts in the minute marks. Then the dial goes to an artist, who, holding it under a magnifier, paints the words "NATIONAL -WATCH co. " in black enamel with a fine camel's-bair brush. The inscription measures three-fourths of an inch from left to right, and less than one-ninetieth of an inch up and down ; but even then it is perfectly legible; and the swift, cunning fingers will paint it twice in five minutes. "Is it not very trying to your eyes?" "If I were to do it all day, or even for an hour steadily," the painter replies, " they would ache terribly. But I put the inscription on two dozen dials, and then rest my sight by painting on the figures, lines, and dots." "My father," observes the superintendent of the room, who is looking over his shoulder, " was an English dial painter. Once he traced the Lord's Prayer with one of these camel'shair brushes on asurface one-eighth of an inch long by one-ninth of an inch wide. Half the wing of a common bouse-fly would cover it. It a,qed the old gentleman's eyes twenty years for his work, but he could see objects at a distance just as well as ever." One can only wonder that it did not strike him blind.

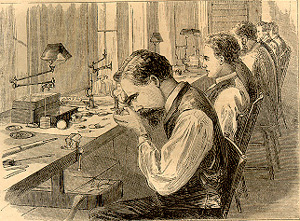

In the Finishing Room we find a drawer full of mainsprings, coiled so loosely that each is as large as a breakfast saucer. One drawn out straight will be two feet long. It is polished like a mirror, and tempered to a beautiful deep blue. A girl coils one to the diameter of a thimble, and then, rifling one of the birds'nests, inserts the mainspring in its brass " barrel," the head of which is held in by a groove like the head of a flour-barrel. This circular chamber, only seven-tenths of an inch across, contains the whole power of the watch. One end of the mainspring is fast to the shaft which pnsses through it, and by which it is turned; the other, as it uncoils, carries around the barrel, and so communicates motion to the train. She puts the parts together temporarily, inserting only screws enough to keep them in place. Her flying fingers set up ninety watches and empty ninety birds' nests every day. The latter go back to the Plate Room for more eggs and fresh incubations; here at least there are always birds in last year's nests. Hair-springs are made in the factory, of finest English steel, which comes upon spools like thread. To the naked eye it is as round as a hair, but under the microscope it becomes a flat steel ribbon. We insert this ribbon between the jaws of a fine gauge, and the dial-hand shows its diameter to be two twenty-five-hundredths of an inch. A hair plucked from a man's head measures three twenty-five-hundredths-one from the bead of a little girl at a neighboring bench two twenty-five-hundredths. Actually, however, the finest hair is twice as thick as the steel ribbon, for the hair compresses one-half between the metallic jaws of the gauge. A hair-spring weighs only one-fifteen-thousandth of a pound Troy. In a straight line it is a foot long. With a pair of tweezers we draw one out in spiral form until it is six inches long; but it springs back into place, not bent a particle from its true coiling. It must be exquisitely tempered, for it is to spring back and forth eighteen thousand times an hour, perhaps for several generations. A pound of steel in the bar may cost one dollar in hair-springs it is worth four thousand dollars. After the watch has been run a few hours, to adjust the length of the hair-spring, it is "taken down," and all the brass pieces sent to the GildingRoom. There each part is polished for electro-gilding. Gold coin is first rolled out into sheets, and then dissolved with acids. At some stages it looks like nauseating medicine, but when it goes into the battery the solution is as colorless as spring-water. But it is a deadly poison. A girl in this room was kept at home for three weeks with sores upon her hand caused by dipping it in the liquid. Twenty or thirty of the brass plates and wheels are hung by a copper wire' in the inner vessel or porous cell of a galvanic battery, filled with this solution, and the silent electric current deposits the gold evenly upon their surfaces. Ordinarily they are left in it about six minutes the quick, educated eye of the superintendent determines how long. A twenty dollar gold piece will furnish him with heavy gilding for six hundred watches, but he could make it gild four thousand so that they would look equally well on first coming out; or he could put five hundred dollars upon a single one-leaving the gold an inch thick all over the works-and it would look no better. All the pieces come out clothed in vellow, shining gold, and are sent back to the finishing Room, put together again, and then turned over to the "watchmakers"-the only persons in the factory necessarily familiar with all parts of the watch. A dozen sit in a row, in a very strong light, before a long bench strewn with their minute brushes, tweezers, magnifiers, and glass cases which cover small mountains of wheels and pinions. They insert the balance and hairspring, see that everything has been properly fitted, and put on the dial.

Then the watches, each in a little circular tin case, go in boxes of ten to the lynx-eyed Inspector, who scrutinizes every part for the slightest flaw or defect. Here is a box which has passed through his hands. Upon two watches are little slips of paper, one labeled "Fork strikes potance"-a slight but needless friction; the other, "Fix the number"-the figures upon some one piece being wrong or illegible. About one-third are thus sent back to the watchmakers, "after his rigid examination. The last scene of all is the adjusting. In his quiet little room the Adjuster keeps the Equator and the North Pole always on hand and ready for use in large or small quantities. First he runs the watch eight hours in a little box heated by a spirit-lamp to one hundred and ten degrees Fahrenheit. Then he runs it eight hours in a refrigerator, where the temperature is nearly at zero. It must keep time exactly alike under these two conditions. If he finds any variation he changes the position of the screws in the compensation-balance, or substitutes new ones, first carefully weighing them in a pair of tiny scales of his own contriving. When we ask him to show us the minutest weight they will indicate he places a bit of whisker upon one end, and adjusts the weight. The speck of hair weighs a trifle over the fiftyseven millionth of a pound Troy. The watch is next carefully adjusted to keep equal lime in different positions. Then it is ready for the case. Its different parts are composed of one hundred and fifty-six pieces. The old watch, made by hand, contained eight hundred pieces, if we count each link of its chain as a separate part. Reducing the number fourfifths has correspondingly reduced its intricacy, friction, and difficulties of repairing. The proprietors realized from the outset that they could only succeed by making good timekeepers. To that one result all their energy has been directed. Manufacturing upon this large scale involves the use of so much capital that after a fine watch is finished and running they can not keep it a year for adjusting and regulating, as jewelers used to do under the old method. Most of their watches have gone out warm from the factory, but they have run with wonderful accuracy. The very first half dozen used upon the Pennsylvanin Railway were brought in by the engineers at the end of six days, and the greatest variation among them was eight seconds. The railroad is the great critic. Nowhere else is a watch so severely tested; nowhere else is accuracy so absolutely essential. After careful trial, solely upon their own merits, the Elgin watches have been adopted as the standard upon several of our leading trunk lines. On the Pennsylvania Road alone more than a hundred locomotives are run by them, and they are in use among conductors and engineers upon every railway in the Northwest, and upon the great trans-continental line from Omaha to San Francisco. That is as it should be the Pacific Railway trains run by American watches. Several months ago a Swiss imitation, labeled "Chicago Watch Company," began to appear in our markets. It looks well to unskilled eyes, but is so rough and cheap that the "movement" can be sold for five dollars after paying the import duty. And lately another imitation, bearing the same inscription, but manufactured in an Eastern factory, has made its appearance. Buyers who would be sure of avoiding these spurious watches should purchase only of some reputable and established jeweler, and never of unknown, irresponsible parties, however honeyed and seductive their advertisements. But this counterfeiting, both foreign and domestic. of an American product less than two years old, at least shows that the genuine article has won enviable reputation. Two facts in the consumption of the Elgin watches are the shadows of coming events. First, fully half, thus far, have been sold in the East, and a large proportion of them in New England. Second, the Company are filling orders for India, which have come from London, without solicitation or advertising abroad. The prairies are beginning to manufacture for the Orient! What will this grow to in the near future, when three Pacific railways bring India, China, and Japan to our doors ? The Company make "movements" alone, dealing with the public only through local jewelers, whom they leave to case each watch according to the customer's taste or fancy. Making cases-a business quite distinct from making watches-is done on a large scale by two or three houses in the United States, and on a small scale by a great many. Crystals cost the jeweler from two and a half to seventy-five cents apiece. The finest are made in Europe; cheaper ones in New York and Pittsburg. Gold cases cost from fifty to one hundred and fifty dollars each ; silver ones from six to thirty dollars; German silver about three dollars and fifty cents. Thus we have followed the watch through its various stages until it is ready for the pocket. An expert jeweler working by hand might perhaps make a watch in three weeks. The Elgin factory, with less than four hundred and forty employees, turns out one hundred and twenty- five a day, or one every three days and a half for every worker in tile establishment, including all the young boys and girls, the book-keepers and clerks. As eighteen is to three and a half so is machinery to hand-work. In watchmaking alone, within the last fifteen years, American inventiveness has increased the efficiency of human labor more than fivefold. Increase in product always brings a still larger increase in demand. When Denison conceived the daring project of manufacturing three thousand watches a year, his sober friends fancied that he could never find purchasers. Since then our imports have increased enormously. In 1868 we bought two hundred and fifty thousand watches, costing four millions of dollars, from Switzerland alone. About one fifth were gold; the rest silver. An enormous proportion were of the grades which sell without cases for from five to ten dollars each, and which as time-keepers are worth about the value of the powder it would take to blow them up. In addition to this foreign supply, one hundred thousand watches a year are now manufactured in the United States. Still the demand is so great that the Elgin factory is often two or three months behind its orders for the most popular grades. The same is doubtless true in other establishments. It will continue true in the time not far distant when a good watch in a silver case can be purchased any where for ten dollars, and when American factories are turning out a thousand watches a day, for the United States and Europe, and swarming Asia. But no degree of familiarity can ever take the charm and interest from a great watch factory: It will always be a magician's palace, which makes the story,of Aladdin prosaic and commonplace.

Ready for the pocket.

|